Earlier this month, I was a speaker at the Lean Systems Summit in Portland, Maine. The focus of my presentation was conflict – namely that its existence is what drives waste. Though I’ve shared a link to my PowerPoint, it was mostly a guide to help focus listeners around key ideas and feels a little bare without my narrative. So, below is an overview of the talk’s main points.

The Pursuit of Better Performance

All Lean is implemented in an effort to improve performance in some way. Whether you’re after better capacity, culture, customer insight, capability or competitive advantage these investments are intended to lead to a more successful future state. Yet despite the fact that it promises lower costs, better working conditions and environments, higher productivity and profits – getting people on board with Lean or getting Continuous Improvement to stick is universally difficult. Why?

Behavioral Blocks

A quick poll of the audiences’ experience with stalled, failed or reverted Lean implementations revealed a range of BEHAVIORS that hindered progress. This is because behavior, not just process is to blame for the loss of productivity. All behavior is an expression of a need unmet.

How many of these have you experienced?

- Little to no buy-in

- Lack of leadership support

- Resistance to change

- Everyone wasn’t aligned

- Competing or unclear goals

- Not a priority

Most lean initiatives, however, don’t consider this very human component of the equation.

Waste Hiding in Plain Site

All of the Continuous Improvement tools we use (Lean, Six Sigma, Theory of Constraints, Agile, etc.) focus on removal and elimination of waste. But these tools only tackle what we can see. The eight wastes, for example, are mostly physical manifestations of deeper seeded issues. This is why, sooner or later, the same issues Continuous Improvement (CI) initiatives were designed to fix, crop up again.

At the root of the behaviors that impede progress or prevent us from succeeding in our continuous improvement efforts is some sort of conflict. If you want to eliminate waste for good you need to eliminate conflict.

Here are some common examples of where it might reside:

- Territorial managers

- Chronic pain between departments

- Low morale

- Failure to use / learn new systems

- Failure to progress with performance goals, missing deadlines

- Failure to address and resolve known issues

Session attendees also saw conflict in these areas:

- Misunderstandings between coworkers

- Focusing on my goals, not what’s good for everyone

- Sales versus operations

- Poor communication in general

- Trying to be nice – not holding people accountable

Exploring Conflict

For most people conflict evokes negative feelings. So despite the fact that unlike waste, we can readily spot conflict, our negative perception of it prevents us from dealing with it productively if at all. Which then means that we never really eliminate the waste that stands between us and our goals. That’s the bad news. The good news is that we can learn to deal with it, and even learn to think about it differently. Conflict, after all, is just a conversation starter.

To start a conversation properly you need to do a few things:

- Check the reason why you are starting the conversation in the first place. Is it to truly help or serve you? Your motive has to be one of service and empathy.

- Create a message that is rooted in an “I” statement that focuses on how I feel about the behavior and what impact it’s having.

- When you deliver your message make sure that your tone, body language and words are all aligned.

- Then the hardest part…Listen. But really listen. This means you are not crafting your next response. This step requires that you listen carefully for the other person’s needs to understand the root of the behavior.

Conflict in Context

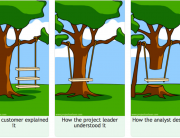

To truly understand and meaningfully mitigate the conflict that drives waste requires exploring the context in which conflicts arise. And to do that, we have to understand the organizational dynamic. At my practice Macresco, we define the organizational dynamic by four components we call SABA: Structures – Activities – Behaviors – and Attitudes.

Most organizations try to drive performance through adherence to structures and activities – the business model, hierarchy and related processes that govern a business operation. The problem with this approach is that it doesn’t consider the behaviors and attitudes that result from this reality. Or considering that those structures and activities may be creating negative behavior or attitudes.

A classic example of a SABA misalignment is the employee that is torn between focusing on quality or volume. Conflict arises for her because the pace at which she must deliver to meet her quota (and compensation goals) is at odds with her natural attention to detail. Her concerns related to quality fall on deaf ears while defects she could help chip away at her bonus and morale.

Another common SABA misalignment is when a company suffers from the schizophrenic strategy that causes business functions to work against each other. Operations is often tasked to reduce cost and frequently addresses inventory as a way to make a significant dent. Problem is that on a balance sheet, inventory equals assets and when Finance feels the pressure to improve EBITDA (because sales go down, because the company wants to sell, or to maintain the stock price for example) they can pressure Operations to undo resizing efforts that may have been months or years in the making. And we wonder why these two camps are frequently at odds.

How Leaders Fuel the Fire

Conflict arises when there is lack of alignment or understanding . . . A key component of your job as a leader of an organization, a division or a team is to help your people have clarity around their purpose, their role, their future and how their success is measured. This is very difficult to do if you don’t have this kind of structure in place, if your organization lacks vision, or does a poor job communicating and holding employees accountable.

5 Tips For Eliminating Waste For Good:

1. Map your SABA.

Understand how your Structures (Business model) and Activities (processes) are driving the prevailing Behaviors and Attitudes and identify where disconnects exist.

2. Listen and watch for others’ needs.

This can be one of the most difficult things to do because we are programmed to provide for our own needs first.

3. Check Continuous Improvement (CI) Initiatives against employee needs.

Is there alignment between program objectives and employee input on process?

4. Understand your own behavioral tendencies.

Leaders often contribute more than they realize to the conflict as a result of their own behavioral tendencies. A little self-awareness goes a long way.

5. Become skilled at starting the conversation.

There are some basic methods that can be adopted to become more skilled at addressing conflict. With practice, you can prevent unresolved conflict from undermining your efforts and derailing progress.

For more information about the workshop Click Here